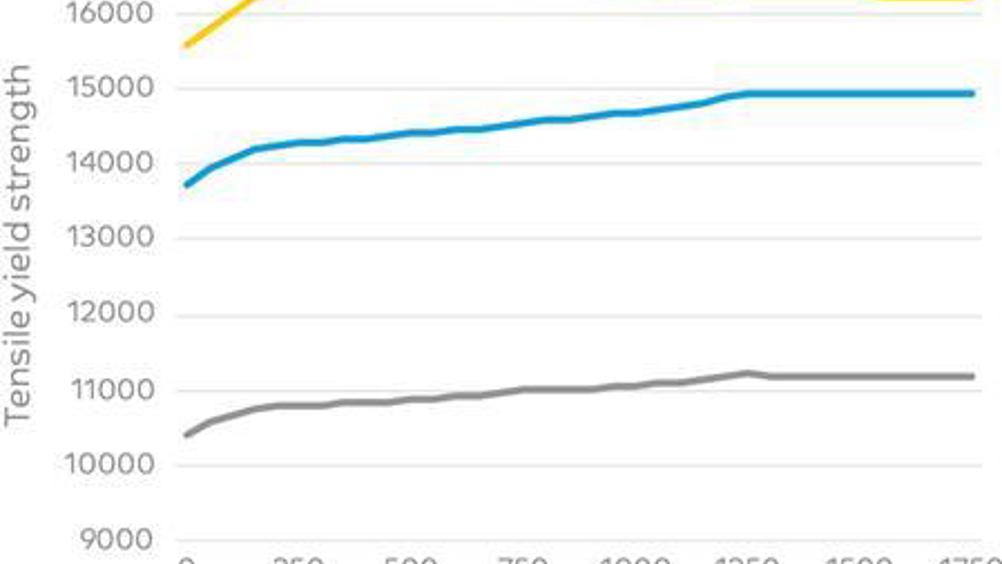

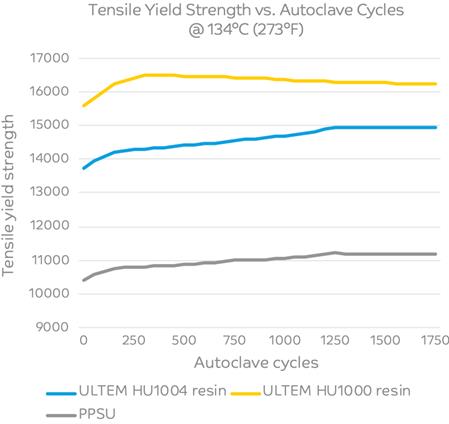

| ULTEM HU resin’s resistance against healthcare disinfectants can help to prevent part failure and avoid costly premature replacements. Plus, ULTEM HU resins are compatible with many mainstream sterilization methods. ULTEM™resin can maintain its physical appearance and mechanical performance after extended sterilization cycles, contributing to a longer life for medical devices. The chart shows that ULTEM HU1000 resin is more than 30% stronger than PPSU, even after extended cycles of steam autoclave sterilization.

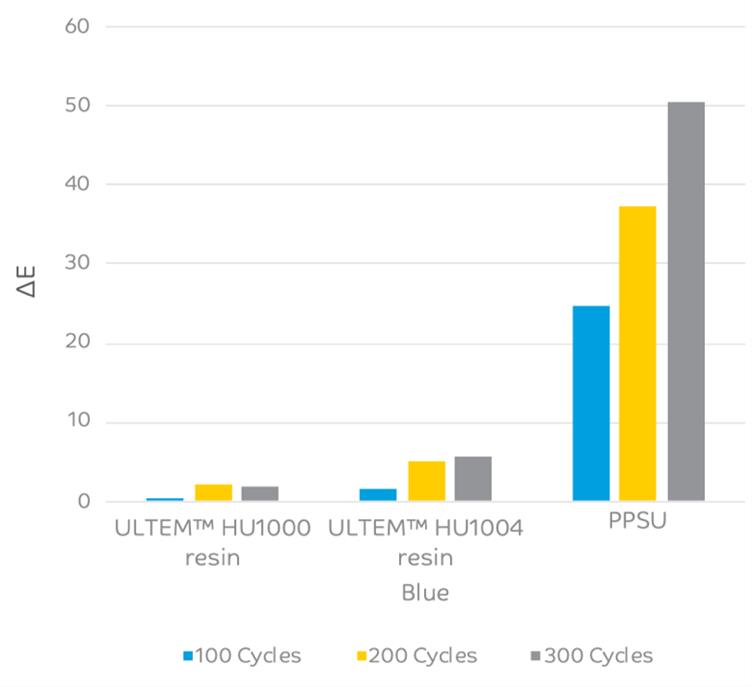

DURABLE COLOR RETENTION: Delta E color change measurements after multiple STERRAD NX sterilization cycles

ULTEM HU1000 and HU1004 resins show minimal color change while the PPSU color deteriorates to a dark greenish hue and embrittles after 300 sterilization cycles. ULTEM resin can help your parts maintain their color and aesthetics even after repeated sterilization cycles. With high compression strength and rigidity even at thin gauges, ULTEM™resin is among the most dimensionally stable thermoplastics available. Designing with ULTEM™resin can help you to achieve stiffness and precision control comparable to metal. ULTEM™resin’s superior strength to weight ratio and higher tensile strength helps to ensure durability and functionality, contributing to a longer useful life. With ULTEM™resin, you can enjoy the design freedom to manufacture light weight complex components that can offer better usability and ergonomics, and that are easier and faster to produce versus metal leading to potential cost savings. Unfilled ULTEM HU1000 resin has 26% higher compression strength vs PPSU, helping to enable efficient transfer of force and minimize compression under load. When even higher compression strength is required, glass fiber reinforced grades HU2200 or HU2300 resin are well-suited options. Consider ULTEM™ resin as your material solution for medical devices that can stand up to multiple sterilization processes and cycles. Sterilization methods have the potential to degrade medical devices over time, diminishing their mechanical integrity, interfering with performance, or altering aesthetics. The EPA ruling on the monitoring of EtO sterilization emissions is on the horizon. Give your customers peace of mind with a material solution that is stable across a multitude of sterilization methods and repeated cycles. • Vaporized Hydrogen Peroxide gas plasma (VHP) >300 cycles • Steam autoclave at 134°C >1000 cycles • Gamma radiation, electron beam, and X-ray • Ethylene Oxide (EtO) • Ultraviolet C (UV-C) 5 kJ/cm2 dose ULTEM HU RESINS HAVE A SUPERIOR ABILITY TO RETAIN COLOR AND AESTHETICS

SABIC’s study tested the performance of ULTEM HU1000, ULTEM HU1004 resin and PPSU in at least 300 sterilization cycles in STERRAD NX, STERRAD 100NX plasma and AMSCO V-PRO vapor systems. ULTEM HU1000 and HU1004 resins show minimal color change versus the control while PPSU shows significant color change.

To discover more about how SABIC’s ULTEM™resins can help you, please contact SABIC’s local Irish distributor, Ultrapolymers using ask.healthcare@ultrapolymers.com or visit the website www.ultrapolymers.com. |

Make your medical device Durable, Strong & Sterile

Precision medical devices require material solutions that are both high strength and robust enough to survive a variety of harsh chemical environments and sterilization techniques. With ULTEM™resin from SABIC, here’s how.