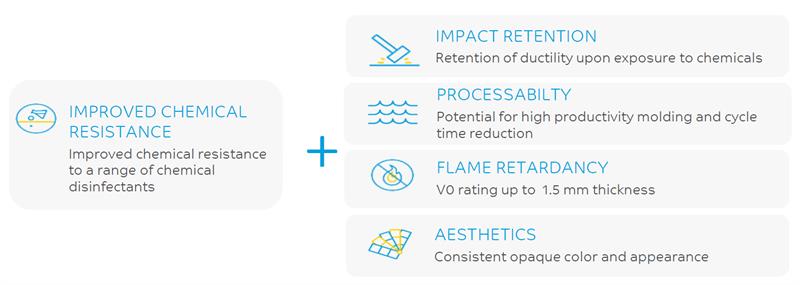

Compared to traditional PC, acrylonitrile-butadiene-styrene (ABS), and polyester and co-polyester resins and blends—which are potentially incompatible with highly aggressive disinfectants such as quaternary ammonium compounds—the new LNP ELCRES CRX copolymers can help prevent stress cracking and mitigate crack propagation.

Adding to their value, these amorphous and semi-crystalline blends can potentially serve as offset solutions in existing injection mold tools for a variety of materials.

These new LNP™ ELCRES™ CRX copolymers offer device manufacturers an easier, drop-in alternative to conventional resins that experience challenges in withstanding repeated cleanings with extremely harsh disinfectants. By adopting these new copolymers, which offer robust resistance to crazing, cracking and discoloration, customers can help enable longer device life and avoid premature replacement.

https://www.sabic.com/en/news/21926-sabic-launches-at-mdm-west-2020-new-lnp-elcres-crx-pc-copolymers